Solid silicone rubber is classified as HTV (High Temperature Vulcanized) silicone rubber.

HTV silicone

HTV silicone is used in the compression molding process. Special types of silicones are selected depending on their intended use, whether they have to be resistant to fire, oil or heat. Food contact silicones for use in the food industry are approved by the U.S. Food and Drug Administration (FDA) and the German Federal Institute for Risk Assessment BFR (Bundesinstitut für Risikobewertung)

HTV silicone is widely used to replace petrochemical products in all industries including aerospace, defense, automotive, fine chemicals, construction, electrical and electronics, food processing, mechanical engineering, medicine and pharmacy, cosmetics, household appliances and semiconductors. Recently, the range of silicone applications has been expanding at an ever faster pace.

GGF TMRubber has long been a manufacturer and supplier of solid silicone products. As a manufacturer, we offer very good quality solid silicone products for customers who are looking for economical solutions at an affordable price.

Properties of silicone rubber (HTV)

- Temperature resistance: silicone rubber can withstand extreme temperatures and remain stable under extreme stress and harsh conditions without being affected by use. Due to the use of special additives (stabilizers), it can work for a long time at temperatures from -90 ℃ to even + 350 ℃.

- Durable: silicone rubber has excellent insulation properties, oil resistance, aging resistance, which means it has a long service life

- Other properties: silicone rubber also has excellent weather and UV resistance properties

Application of silicone rubber (HTV)

Currently, the use of silicone rubber (HTV) is becoming more widespread in the aerospace industry for the production of components used in the interior and exterior of aircraft. Solid silicone rubber also has applications in the automotive, electronics and other industries such as machinery, construction, textile, chemical, light and printing.

What is the difference between HTV silicone and LSR?

Solid silicone (HTV)

Solid silicone contains polymers of high molecular weight and relatively long polymer chains. It is defined as HCR (high consistency rubber). We offer two ranges of solid silicone rubber products: vulcanized with peroxide and grades (platinum catalysed) The standard form of the base material is 90 x 100 mm (cross-section) blocks that are wrapped with PE foil

Liquid silicone (LSR)

Liquid silicone rubber contains polymers of lower molecular weight and therefore shorter chains. It also has a wider range of properties. Liquid silicone is always cured with a platinum catalyst and is referred to as LSR (liquid silicon rubber). LSR grades are delivered as two-component systems. Component A contains a platinum catalyst and component B contains a crosslinker. It is delivered in two capacities

- 20 kg drums

- 200 kg drums

The use of HTV silicone

HTV silicone is widely used in the aerospace, defense, automotive, precision chemistry, construction, electrical and electronic, food processing, mechanical engineering, medicine, pharmacy, cosmetics, household appliances and semiconductor industries. Recently, the scope of use of silicone has been expanding at an ever faster pace.

Characteristics of HTV:

Durability: Silicone rubber is the material of choice in the industry when it is desired to maintain its original shape and mechanical strength under conditions of high thermal stress or freezing temperatures. Silicone rubber is used wherever there is exposure to ozone, UV radiation, heat and other aging factors that silicone rubber can withstand well. This makes silicone rubber one of the elastomers of choice for many extreme environments.

Chemical resistance: HTV silicone is highly inert and will not react with most chemicals. Due to its indifference, it is used in many medical applications, including medical implants. It is biocompatible, hypoallergenic and antiallergic, making it suitable for baby care products and food contact in general.

Mechanical properties: properties such as tensile, creep, cyclic bending, tear strength, compressive deformation, dielectric strength (at high voltage), thermal conductivity, fire resistance, – at extreme temperatures, are significantly better than organic rubbers in general, although some of these properties are still lower than some specialty materials.

Electrical properties: HTV silicone has excellent insulating properties.

Types of solid silicone

Products for our clients are made of two types of solid silicone (vulcanized with peroxide) and (with a platinum catalyst, vulcanized with addition).

We can choose between the base and ready-to-use mixtures. The product offer is completed by cross-linking agents, stabilizers, pigments and other additives.

Peroxide vulcanized products combine the advantages of solid silicone rubber with those of liquid addition silicone rubber, namely excellent mechanical properties combined with high performance. Permanent silicone is available as one-component component.

Grades of solid peroxide vulcanized silicone rubber. They can be processed by conventional methods such as extrusion, calendering, pressing, transfer molding or injection molding. They are hot vulcanized and are ideal for the production of various silicone rubber articles.

The use of solid silicone

Hot-vulcanized silicone rubber is used in a variety of industries and in all industries:

- Automotive and aviation

- Electrical engineering

- Transmission and distribution cables (T&D)

- Construction

- Mechanical and plant engineering

- Consumer goods and the food industry

- Healthcare and medical technology

Methods of solid silicone processing

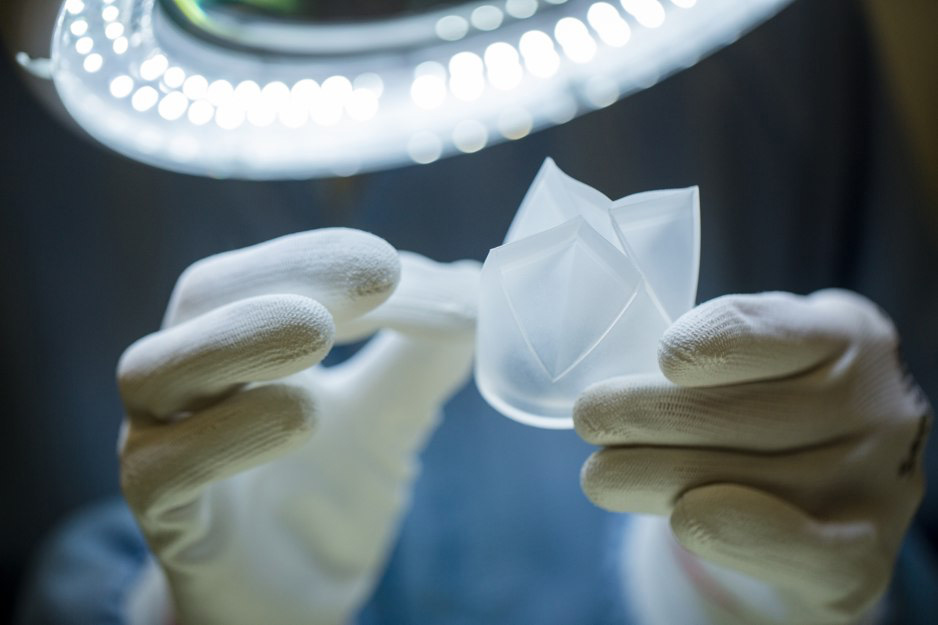

Compression moulding of solid silicone

Pressing is the basic production process in which silicone rubber is pressed between the die and the mold punch and then vulcanized with heat. The matrix gives the material its shape. Silicon is administered manually in precisely measured doses to each of the nests or transferred. Transferring is a method similar to processing liquid silicone by means of injection, with the difference that here we use solid silicone which is placed in the chamber where it liquefies as a result of compression with a piston and is transferred through the gating channel directly to the closed mold cavity.

Injection molding

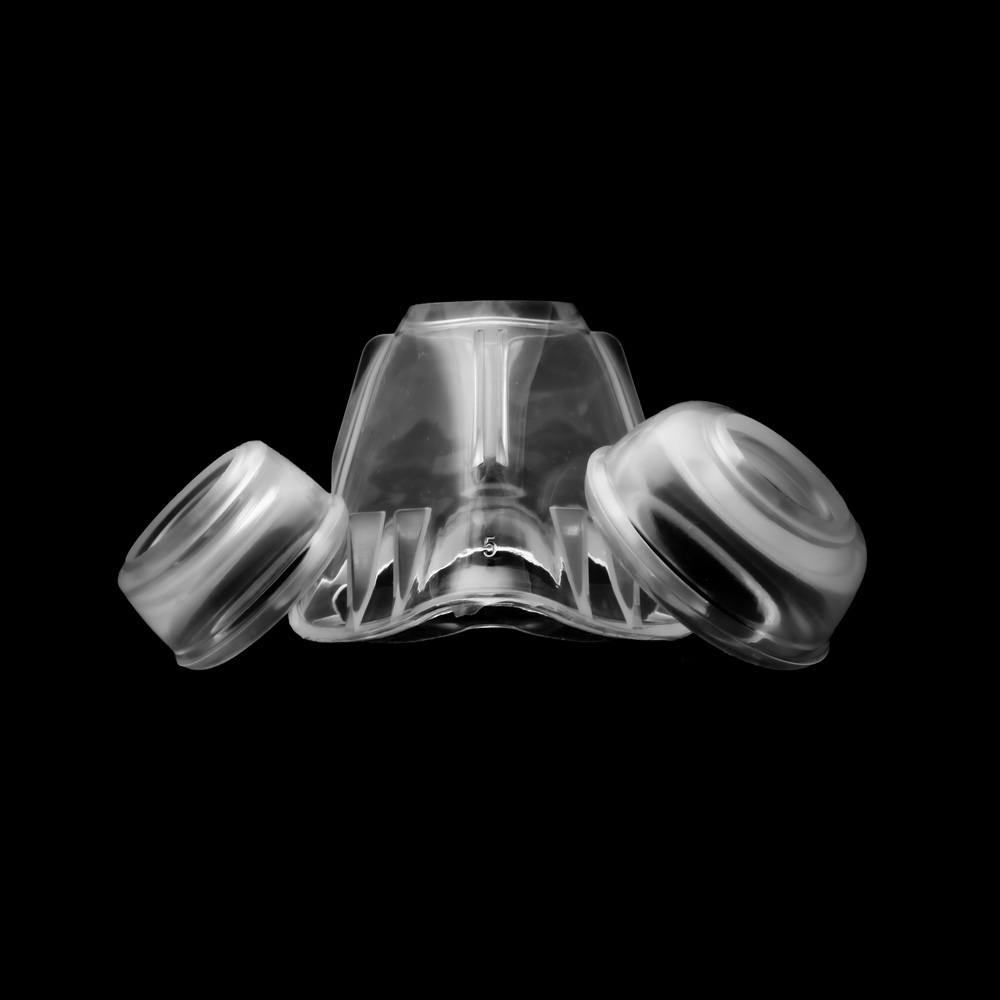

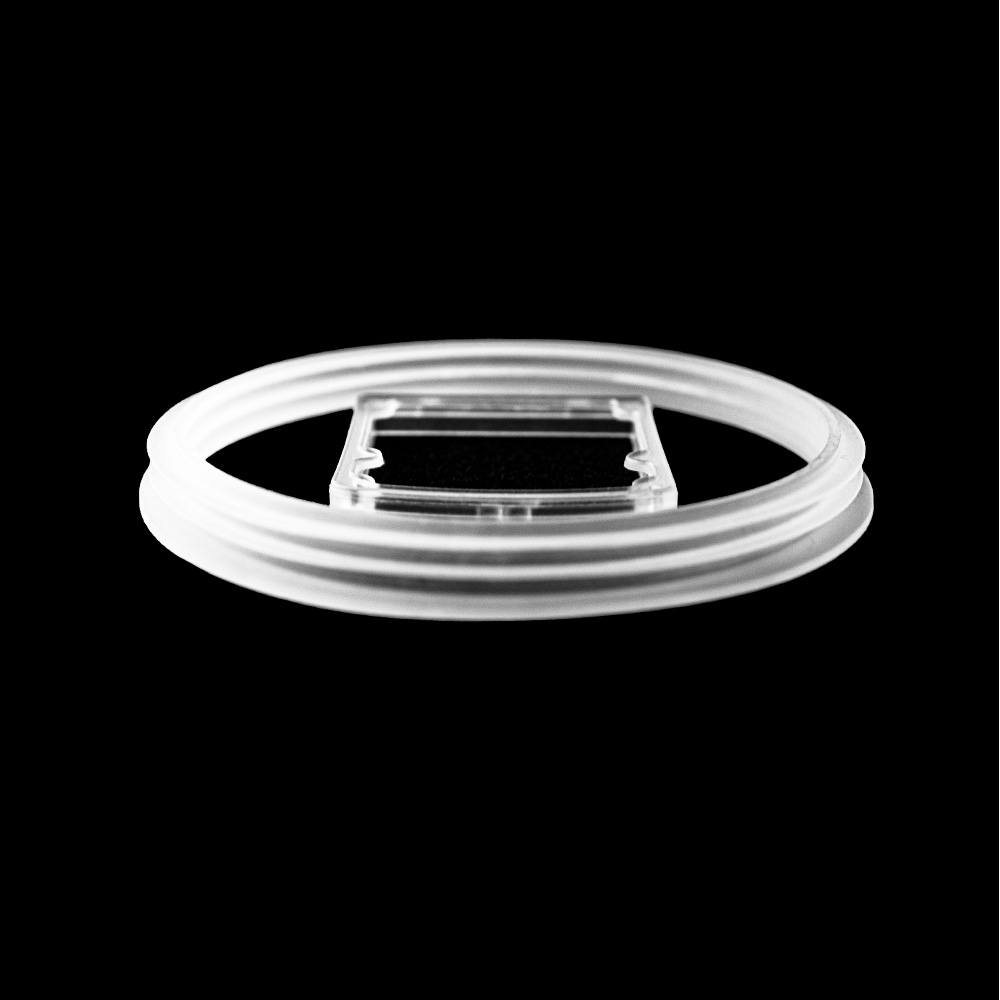

Injection molding is the most popular and efficient process to mass-produce products that must meet stringent requirements for consistently high quality. It is characterized by high dimensional accuracy, high quality of parts without the need for secondary finishing and allows for much shorter production cycles than other processes. The disadvantage is the higher cost of molds and machines, which are counterbalanced by high efficiency. Injection molding is ideal for small to medium parts and large production runs such as:

Injection molded products include:

- Teats for baby bottles

- Sealing rings

- Vacuum suction cups

- Membranes

Transfer molding of solid silicone - extruding

Extrusion is another method of processing solid silicone using heat with or without the use of pressure. It is suitable for the production of tubes and longer profiles. Typically, peroxide vulcanized silicones are used with this method. Extrusion usually takes place at a temperature of 200 to 500 ° C and requires only a few seconds. In this process, the silicone is constantly pressed through the so-called „Mouthpiece” giving the desired shape and size of the profile. Vulcanization can be done in horizontal and vertical units. In horizontal units, the material is conveyed on a belt or mesh conveyor through the vulcanization chamber. In vertical units, the drawpiece is lowered under its own weight. Both horizontal and vertical curing chambers can be: heated with belt heaters, infrared units, heating mantles or any other clean source of heat. In addition, horizontal chambers can be heated with an air stream, ensuring very fast and efficient heat transfer.

Extruded products include:

- Tubes

- Profiles

- Wires

- Flat belts

- Round cords