Additives can be used to enhance specific properties of silicone to meet extreme demands. The additives are introduced directly with an internal mixer in the case of liquid silicone (LSR) or in a rolling process in the case of solid silicone (HTV) to adjust the properties of the silicone to the specification.

Why is it worth using silicone additives?

Silicone additives improve the heat stability, fire resistance and formability of solid silicone. Some additives provide specific properties, such as magnetizability, resistance to X-rays, resistance to aggressive media (oils, fuels, alcohols).

And if we have specific color requirements, we have a range of pigment pastes with which we can achieve almost any shade imaginable.

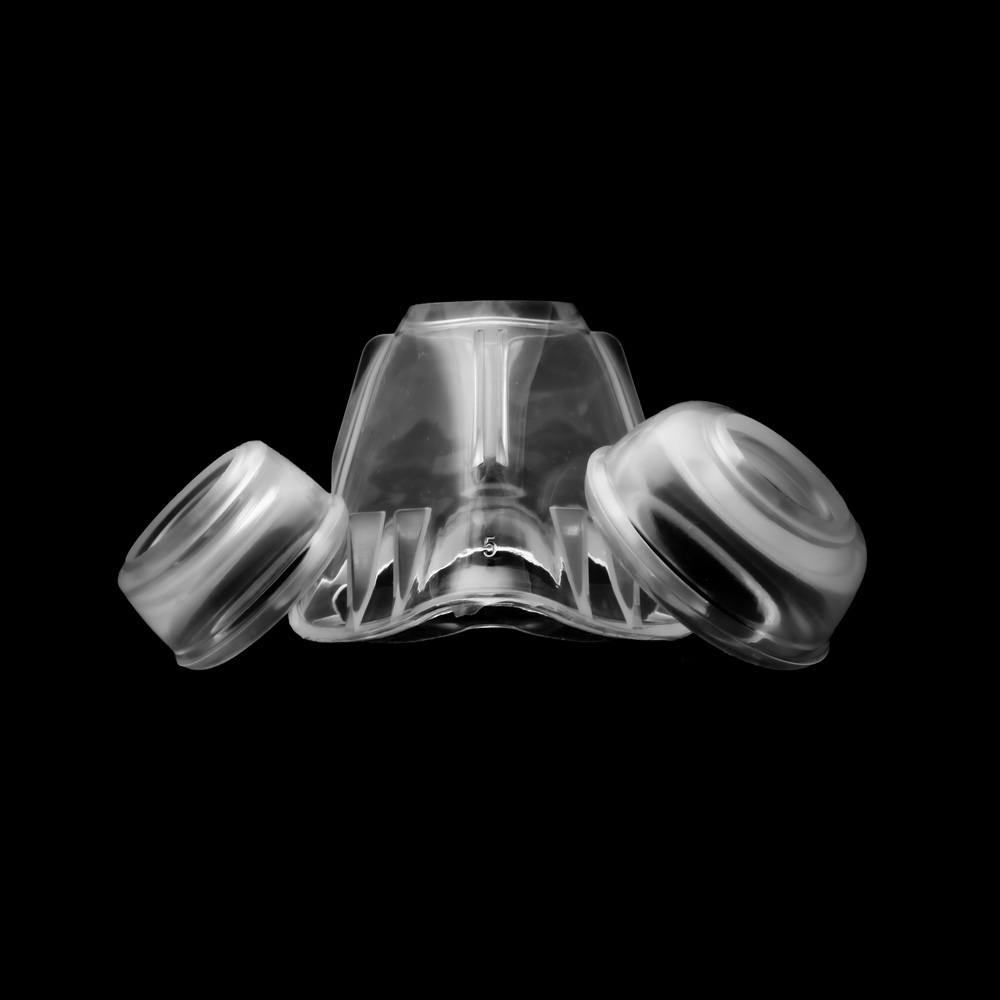

Moreover, solid colors are just as easy to make with silicones as they are translucent.

Fluorescent additives for silicone

An interesting feature, however, is the visibility under UV light. With the help of fluorescent additives, we can obtain a silicone that emits a deep blue-violet glow when exposed to UV light.

Silicone processors can use this property to develop automated quality control systems for their production setup.